As a business grows and product demand increases, expanding and upgrading existing manufacturing facilities to meet production and workforce needs becomes necessary. Manufacturing companies often consider expanding their facilities to increase production capacity, improve efficiency and reduce costs but in a tight economy, workforce issues also need to be prioritized. Upgrades to facility design, lighting, workspaces, restroom facilities, modernizing equipment and providing training are key to successful workforce retention and production expansion. Upgrading a manufacturing facility requires a significant investment. One North Carolina manufacturing facility realized that to meet new opportunities on a challenging timeline, it would need to partner with an organization with a track record of excellence.

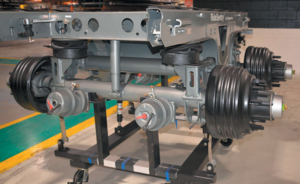

Cummins-Meritor provides components for commercial vehicles across the globe. The products produced at the Cummins-Meritor facility in Morganton, North Carolina, are integral to the supply chain, providing American-made axles for over-the-road commercial transportation. As the need for a US-based supply chain grew, so did opportunities for this North Carolina manufacturer. The company’s product portfolio includes axles, brakes, carriers, drivelines, e-powertrains, gearboxes, suspensions, transfer cases and transmissions. These products are designed to deliver optimal performance and fuel efficiency, serving the commercial transportation, fire and rescue, construction and utility, materials handling, agriculture, railways, and defense industries.

Cummins-Meritor provides components for commercial vehicles across the globe. The products produced at the Cummins-Meritor facility in Morganton, North Carolina, are integral to the supply chain, providing American-made axles for over-the-road commercial transportation. As the need for a US-based supply chain grew, so did opportunities for this North Carolina manufacturer. The company’s product portfolio includes axles, brakes, carriers, drivelines, e-powertrains, gearboxes, suspensions, transfer cases and transmissions. These products are designed to deliver optimal performance and fuel efficiency, serving the commercial transportation, fire and rescue, construction and utility, materials handling, agriculture, railways, and defense industries.

“In 2021 a potential new client approached us asking for an incremental supply of trailer axles,” said Cummins-Meritor Morganton site manager Kevin Roy. “They wanted to onshore their operations from China but their request exceeded our capacity. We realized we would need to upfit our operations and equipment.” When Cummins-Meritor purchased its Morganton plant in 2015, it was in for many necessary upgrades. “The plant required investment due to aged equipment and infrastructure,” said Roy.

“In 2021 a potential new client approached us asking for an incremental supply of trailer axles,” said Cummins-Meritor Morganton site manager Kevin Roy. “They wanted to onshore their operations from China but their request exceeded our capacity. We realized we would need to upfit our operations and equipment.” When Cummins-Meritor purchased its Morganton plant in 2015, it was in for many necessary upgrades. “The plant required investment due to aged equipment and infrastructure,” said Roy.

In December of 2021, the Cummins-Meritor facility in Morganton began a transformation focusing on capital investment and production excellence. Cummins-Meritor received support from the Economic Development Partnership of North Carolina (EDPNC) to invest in their facility and equipment to meet increasing demands. The North Carolina Manufacturing Extension Partnership (NCMEP) partner, EDPNC, is dedicated to attracting new business to North Carolina, supporting existing businesses, increasing global exports and supporting onshoring manufacturing worldwide.

(Pictured L-R: Jerry Krug, Meritor General Manager, Kevin Roy, Meritor Morganton Site Manager and Bill Slagle, Director of Existing Industry Expansion at EDPNC)

The Cummins-Meritor team met EDPNC by connecting with the local economic development organization, Burke County Industries (BDI). “We contacted BDI to inquire about our eligibility to work with EDPNC,” said Cummins-Meritor general manager of industrialization Jerry Krug. “BDI was instrumental in facilitating a relationship with the state-level economic development organization.”

Bill Slagle, the director of statewide and northwest existing industry expansions at EDPNC was the liaison between Cummin-Meritor and EDPNC. Through his swift collaboration with Krug, Cummins-Meritor obtained a grant to assist in funding facility upgrades to meet the opportunity timeline to increase production to meet the needs of the onshoring opportunity. “We worked with Cummins-Meritor to obtain subsidized funds for building reuse efforts such as high-efficiency LED lighting and upgraded facilities plumbing. The improvements were key to attracting and retaining the workforce needed to increase production in a competitive manufacturing community. The organization was also granted funds for training to educate their workforce on new technologies.”

“Over the past few years, the company has invested several million dollars in updating the equipment and improving the facility,” said Krug. The investments made to the Morganton facility have improved efficiency and capacity, reduced costs, created new jobs and retained employees to continue substantial growth. Cummins-Meritor in Morganton increased sales by approximately 15% from 2021 to 2022.

“Over the past few years, the company has invested several million dollars in updating the equipment and improving the facility,” said Krug. The investments made to the Morganton facility have improved efficiency and capacity, reduced costs, created new jobs and retained employees to continue substantial growth. Cummins-Meritor in Morganton increased sales by approximately 15% from 2021 to 2022.

As a result of working with EDPNC, Cummins-Meritor recognized $8,150,000 in economic impact, with 25 new jobs created and 25 retained. There was $1,000,000 in retained sales, $100,000 in cost savings and a $3,500,000 investment in plant equipment.

When reflecting on the alliance with EDPNC, Krug stated, “EDPNC’s support, response timing and efficiencies in processing have been impressive. All parties worked together well to facilitate a successful outcome. We feel the intent of goal-driven success is evidence based on efforts and attention afforded to Cummins-Meritor through the program’s execution.”

When reflecting on the alliance with EDPNC, Krug stated, “EDPNC’s support, response timing and efficiencies in processing have been impressive. All parties worked together well to facilitate a successful outcome. We feel the intent of goal-driven success is evidence based on efforts and attention afforded to Cummins-Meritor through the program’s execution.”