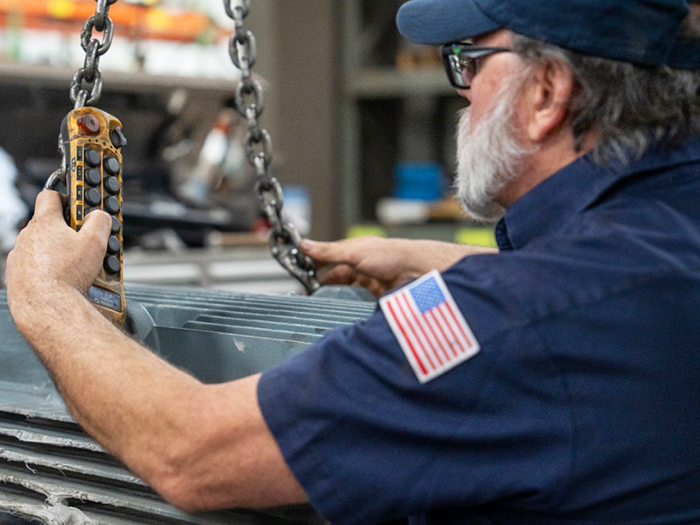

Jenkins Electric is a family business in Charlotte, North Carolina, specializing in repairing, maintaining and testing electric motors and industrial electromechanical equipment. Jenkins Electric serves the heavy manufacturing, hydroelectric power generation and utility industries with a commitment to delivering high-quality repair solutions. The company offers a comprehensive suite of services including motor rewinding, dynamic balancing, vibration analysis and custom fabrication. Jenkins Electric leverages advanced technologies and a skilled workforce to provide reliable and efficient solutions focused on innovation and customer satisfaction.

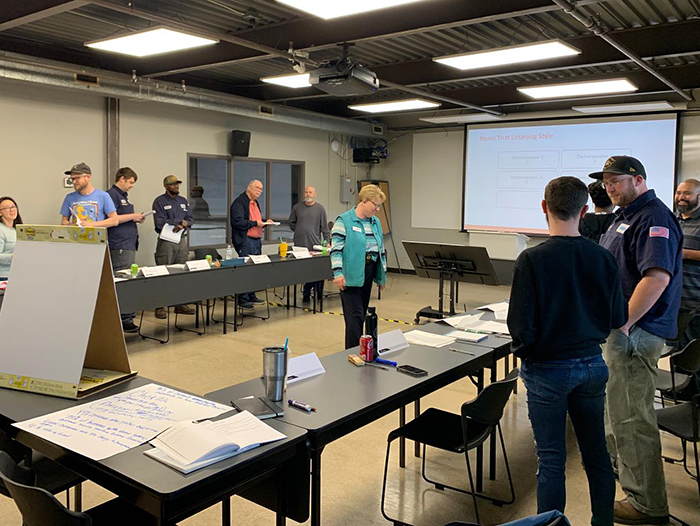

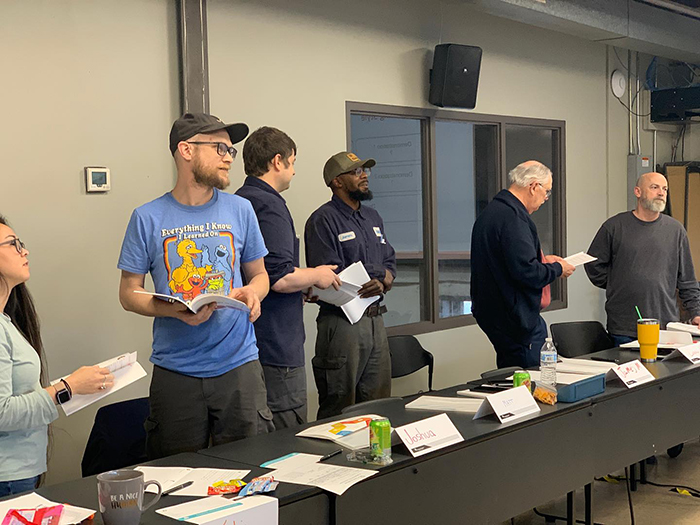

Jenkins Electric is a legacy business with employees ranging from 40 years of service to 18-year-olds just starting their careers. The company needed to maintain high standards while improving efficiency, especially in light of current labor shortages. Jenkins Electric hosted an introduction to Lean principles in their training room with an NC State University Industry Expansion Solutions (IES) representative. The organization’s leadership team, from the President to the operations managers, participated in the training.

“We are currently working on value stream mapping and pursuing our Yellow Belt certification, aiming to introduce these concepts to our technical staff. One of the key insights from Lean 100 was recognizing that Lean is not just a top-down approach but a mindset change for the entire organization, which takes time,” remarked Crystal Bristow, executive vice president of Jenkins Electric.

Much of what Jenkins Electric does isn’t taught in technical schools anymore, as they now focus on transferring the deep knowledge of their long-term employees to the next generation. Specific industry skills still require hands-on training that machines can’t replace. “We noticed a decline in applicants and those we get are often very inexperienced. This realization led us to embrace Lean principles to improve efficiency with our current skilled workforce and those we are developing.” By streamlining current employee jobs, they make tasks more efficient and from a business perspective, prioritize investing in their employees. This approach helped them build a workforce capable of performing the high-level skills they need.

“Meeting regional manager Jennifer Fielder, a regional manager at NC State University Industry Expansion Solutions (IES), was pivotal. She showcased her capabilities and connected us with Central Piedmont Community College for additional management training focused on soft interpersonal skills,” said Bristow. This is crucial, as like many manufacturers, Jenkins Electric often promotes skilled technicians into management roles and this training helps them develop the necessary soft skills to be influential leaders.

A challenge in any legacy manufacturing business is the mindset of “we’ve always done it this way.” This approach can be the secret sauce of many manufacturers, preserving unique, time-tested methods that are no longer taught and can’t be easily replicated. However, there’s a need to evaluate this mindset. “While 50-60% of the legacy methods may be essential, there’s a 40% where we should ask if we can improve efficiency. It’s about assessing whether we should continue establishing practices or identify opportunities to enhance them,” stated Bristow. Overcoming change management hurdles involves balancing respect for traditional methods with openness to new ideas. This means listening to the team, providing them opportunities to apply what they learn, and recognizing that while new methods aren’t always better, improvements can often be made to respected processes.

To simplify employee training, Jenkins Electric adopted a segmented approach, breaking it into smaller, manageable parts to avoid taking up full portions of the workday. “Both IES and Central Piedmont Community College have been excellent in accommodating our schedules, whether we need sessions in the morning or afternoon. This flexibility has been crucial for us, as pulling our full management team off the floor for extended periods like eight hours or two days is unrealistic,” said Bristow. By splitting the training into two groups, the organization ensured that work and production continued smoothly while training was underway.

Through Lean training, Jenkins Electric learned the importance of cross-communication and cross-training across departments. While departments allow for focus, they can also become siloed. “One group might have a very busy week while another has downtime. By fostering cross-communication and using leaders’ diverse skill sets, we can better manage workloads and enhance efficiency. This was particularly evident during the Lean 100 training, specifically the airplane exercise. It was fascinating to see managers with different leadership styles—some taking a strategic, hands-off approach and others diving in and dividing tasks—working together. This highlighted the need for hands-on and strategic leaders and the importance of encouraging them to learn from each other,” said Bristow.

Another key takeaway from the exercise was witnessing our team’s competitive spirit. Not everyone is naturally competitive, but when a team wants to win together, it creates a unique, almost magical dynamic that can’t be manufactured or taught. “The exercise was designed to challenge us, and despite initial failures, our team was determined to improve. We repeated the exercise three or four times, driven to beat our previous numbers. This tenacity and refusal to accept mediocrity, even working through lunch, showcased our team’s commitment to success and the strong, collaborative spirit that defines our culture,” commented Bristow.

“The DiSC assessment was a game-changer for us. We conducted it with our senior and operations leaders, and one of them was amazed by how accurately a quick quiz captured his personality. He even shared his personality profile with his technical team, explaining his direct communication style and emphasizing that his approach is focused on getting the job done, not on personal matters,” explained Bristow. In addition to DiSC, they found two other pieces of training particularly insightful. The first was customer service training for everyone who interacts with customers. This training introduced the concept of internal customers, highlighting that colleagues in departments like accounting and shipping are internal customers who deserve the same level of service as external clients. This perspective shift was eye-opening for many of our team members.

The second impactful training was on leading across generations. “With five generations in our workplace, it helped us understand the different work ethics and motivations of Boomers, Gen X, Millennials, and Gen Z. This training allowed us to see beyond surface behaviors and understand the underlying reasons for different work approaches. As a result, we’ve become better at coaching employees and addressing generational frustrations, leading to a stronger, more engaged team,” proclaimed Bristow. This deeper understanding has been crucial in retaining employees who might view things differently, strengthening their organization.

One of the organization’s main accomplishments for leadership training and lean implementation—areas where they are still evolving—was to break down internal barriers between departments and between legacy employees and new hires, including new managers. “This training has been instrumental in bringing together people who don’t usually interact. It has helped them understand each other’s different ways of processing information and recognize why they might not see eye to eye due to varying personality styles. One of our significant achievements has been removing these invisible barriers, leading to shared staff, improved communication, and more efficient use of time and materials throughout the organization,” stated Bristow.

“Working with IES has exceeded our expectations. Jennifer Fielder and Allison Bowers from Central Piedmont Community College have been true partners, committed to our success with no agenda other than helping Jenkins grow its people. Their dedication stands out compared to our experiences with outside consultants. Alison and Jennifer have taken the time to get to know not just our management staff but also our technicians, machinists, and foundry workers,” stated Bristow.