The Benefits of Smart Manufacturing

Improved efficiency

Smart factories can monitor equipment performance and automate complex processes, improving accuracy and reducing human error.

Increased productivity

Smart factories can use data to identify issues, such as when a machine is slowing down production, and then use artificial intelligence systems to resolve them.

Long-term cost savings

Smart factories can use predictive maintenance to identify potential problems early and address them at a convenient time, which can save money.

Greater flexibility

Smart factories can scale production quickly to meet changing demand and can customize products to meet specific customer needs.

How the program works:

SUBMIT AN APPLICATION

*Important: The company should assign a smart manufacturing project decision-maker.

Project solution plan and cost proposal are to be submitted SMARTER NC for approval of any reimbursements prior to project start. 50 projects will be approved for partial reimbursement of some project non-equipment costs.

*Funding priority will be given to higher energy use projects.

Company completes the approved project with 3rd party and submits the agreed to reimbursement amount for payment.

To receive SMARTER NC reimbursement funds, approved applicants must:

- Submit a detailed cost proposal for the SMARTER NC project subject to reimbursement including itemized labor and materials expenditures

- Obtain a Unique Entity Identifier (UEI). This has replaced the Data Universal Numbering System (DUNS)number.

- Have a procurement review process in place

- Complete an environmental questionnaire as required by DoE

- Receive documented evidence of approval by DOE and SMARTER NC

- Submit evidence of paid invoices for the approved and completed SMARTER NC project

- Complete approved SMARTER NC project and submit reimbursement request before March 15, 2027.

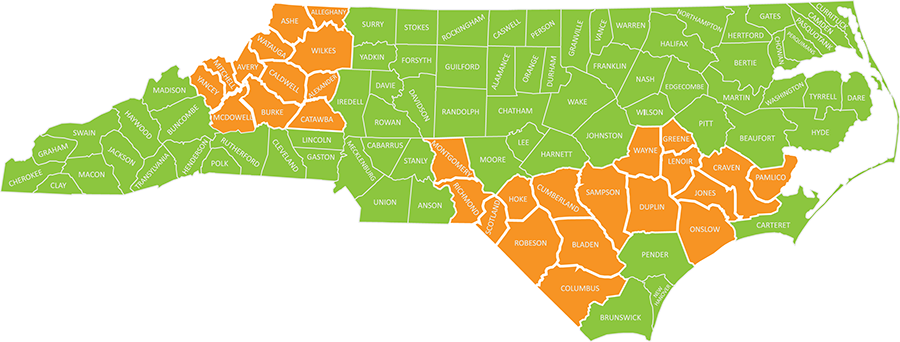

Target Location

(but not limited to)

Prioritize assistance with Small-Medium Manufacturers in 3 targeted rural-based NC prosperity zones

-

Southeast Prosperity Zone

Bladen, Columbus, Cumberland, Hoke, Montgomery, Richmond, Robeson, Sampson, Scotland -

Sandhills Prosperity Zone

Craven, Duplin, Greene, Jones, Lenoir, Onslow, Pamlico, Wayne -

Northwest Prosperity Zone

Alexander, Allegheny, Ashe, Avery, Burke, Caldwell, Catawba, McDowell, Mitchell, Watauga, Wilkes, Yancey

Target Industries

(but not limited to manufacturers in)

- Biopharmaceutical

- Metal Fabrication

- Chemical and Polymer

- Food and Beverage

- Automotive and Heavy Equipment Manufacturing

- Textiles

Additional Resources

Disclaimer: “This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.”