Unraveling the Truth: Seven Common Misconceptions About Lean Continuous Improvement

Lean continuous improvement is a methodology that has revolutionized how organizations operate and strive for excellence. However, like any powerful concept, it is not immune to misconceptions. In this blog, we’ll delve into seven common misconceptions about lean continuous improvement and unravel the truth behind each one.

1. Lean is Just for Manufacturing

One prevalent misconception about lean continuous improvement is that it exclusively applies to manufacturing. Lean principles originated from manufacturing processes, but they have evolved to be universally applicable in other industries as well. Lean thinking can be effectively implemented in service industries, healthcare, IT and other sectors. The core principles of eliminating waste, improving efficiency and optimizing processes are versatile and can be tailored to fit any organizational context.

2. Lean is Only About Cutting Costs

Another common misunderstanding is that lean is solely focused on cost reduction. While cost savings are one of the outcomes of lean practices, the primary objective is to deliver value to customers. Lean encourages organizations to streamline processes, eliminate non-value-added activities and enhance efficiency. By doing so, organizations can improve customer satisfaction, increase product or service quality and experience financial benefits. Lean is a holistic approach that prioritizes value creation over simple cost-cutting measures.

3. Lean is a One-Time Project

Lean is often mistakenly perceived as a one-time project rather than an ongoing process. Some organizations approach lean as a series of isolated improvement projects, failing to recognize that it is a continuous journey. True lean thinking requires a cultural shift within the organization, fostering a mindset of continuous improvement among all employees. Organizations must embed lean principles into their DNA, encouraging employees to constantly seek better ways of doing things.

4. Lean is All About Speed

While speed is an essential aspect of lean, it is not the sole focus. Lean emphasizes the concept of flow, which involves the smooth and efficient movement of materials, information, and processes. It’s not just about doing things quickly; it’s about doing them right the first time. Quality is a fundamental pillar of lean thinking. Organizations should strive for a balance between speed and quality, ensuring that processes are not rushed at the expense of delivering value.

5. Lean Doesn’t Require Employee Involvement

Some may mistakenly believe that a select group of experts can implement lean initiatives without widespread employee involvement. In reality, employee engagement is crucial for lean continuous improvement. Frontline employees often have valuable insights into day-to-day processes and their involvement is essential for identifying areas of improvement. Lean is a collaborative effort that encourages teamwork and empowers employees at all levels to contribute to the organization’s success.

6. Lean is Only for Big Companies

Another misconception is that lean is suitable only for large corporations with extensive resources. In reality, lean principles can be applied to organizations of any size. Smaller companies can often adapt to lean practices more quickly and effectively. The key is to scale lean principles to fit the specific needs and scale of the organization. Whether big or small, any organization can benefit from eliminating waste, improving efficiency and delivering more excellent customer value.

7. Lean Doesn’t Support Innovation

Lean is sometimes misunderstood as a rigid methodology that stifles creativity and innovation. On the contrary, lean thinking promotes a culture of continuous improvement, which inherently encourages innovation. By regularly evaluating and optimizing processes, organizations create an environment that fosters innovation and problem-solving. Lean provides a structured framework for experimenting with new ideas, learning from failures and continuously adapting to changes in the business landscape.

Summary

Debunking these common misconceptions about lean continuous improvement is essential for organizations looking to unlock their full potential. By understanding that lean is not confined to manufacturing, is more than just a cost-cutting tool, requires ongoing commitment, values quality over speed, relies on employee engagement, applies to organizations of all sizes and actively supports innovation, businesses can embrace lean principles with a more precise and more accurate perspective. Embracing a holistic and accurate understanding of lean will empower organizations to drive continuous improvement, enhance customer value and thrive in an ever-evolving business environment.

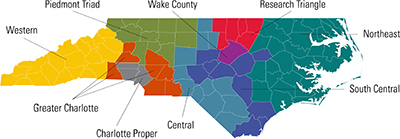

NC State University Industry Expansion Solutions can help you jumpstart your continuous improvement journey! Contact the region manager in your community to get started.

Curious about Lean?